Cotton Grower: Cotton Incorporated’s goal is to enhance the profitability of cotton production through research. To ensure our research aligns with current challenges and builds on past successes, we conducted Natural Resource Surveys of U.S. cotton producers in 2008, 2015, and 2023.

These surveys also serve to demonstrate the sustainability of cotton farming and the industry’s ongoing improvement, providing data for life cycle assessments. This article specifically addresses questions regarding the adoption of precision agricultural technology by cotton farmers.

Farmers in every cotton-producing state took part in the surveys, and the proportion of responses generally matched acres grown in the state (for instance, Texas, with the highest number of planted cotton acres, had the highest number of responses, followed by Georgia, which has the second most planted acres).

In all surveys, the respondents represented at least 9% of acres planted in the year of the survey. Note that region is sometimes referred to in these results, and they are defined as: Far West: CA, AZ, NM; Southwest: TX, OK, KS; Mid-South: MO, AR, MS, LA, TN; and Southeast: AL, FL, SC, NC, VA.

Trending Technologies

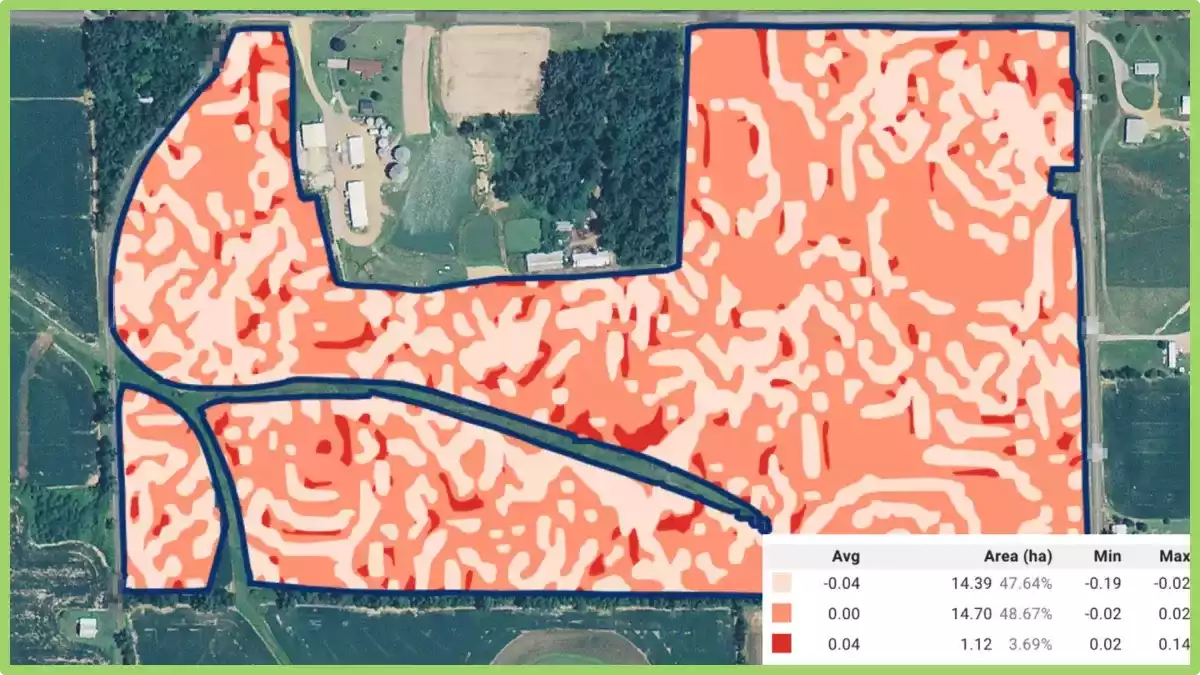

In all surveys, growers were asked to rate 29 production concerns as major, moderate, or not an issue. The top concern in all three surveys was the cost of cotton production. However, as growers can’t control input costs, precision technologies become essential. These technologies help ensure that only what is needed is applied, preventing wastage of money.

Consequently, there has been a rise in the use of various technologies, with the exception of soil sampling, which has remained constant at 46%, as depicted in Figure 1. In the 2023 survey, only 4% of respondents reported not using precision technologies.

It’s important to note that soil mapping and soil sampling referred to here pertain to using samples to address within-field spatial variability, not general soil sampling. For determining fertility rates, 77% of respondents indicated they use soil test recommendations.

The utilization of autosteer technology has significantly increased over time. In 2008, only 46% of farmers used it, but by 2015, the number rose to 69%, and by 2023, it reached 86%. This upward trend demonstrates the growing reliance of farmers on autosteer.

Similarly, the adoption of autosteer and yield monitor technologies aligns with findings from a survey conducted by the USDA Economic Research Service on precision agriculture adoption on U.S. farms. The survey covered multiple commodities, including cotton, in the years 2000, 2003, 2007, and 2019.

In both studies, the adoption rates for yield monitors and autosteer increased. However, autosteer adoption was much higher than that of yield monitors. As shown in Figure 1, the increase in autosteer outpaced all other considered technologies and practices.

Autosteer is becoming standard on new equipment and requires minimal preparation compared to other technologies. Meanwhile, with other technologies, maps need to be downloaded, interpreted, transformed into application rate maps, and re-uploaded.

Autosteer reduces operator stress and can improve input use efficiency by eliminating skips and over-application due to overlaps. It is expected that the increased use of wireless modems in agricultural equipment will ultimately boost the adoption of other technologies when memory cards no longer need to be transported from the office to the equipment.

Additionally, new data analysis techniques are automating the interpretation of soil and yield maps. Agricultural data science consultants are also becoming available to assist farmers in maximizing the value of their data.

There’s evidence that increased ease of use and factory-installed options will facilitate future technology adoptions, as shown by the regional adoption of yield monitors in Figure 2.

The adoption levels of yield monitors in 2015 were correlated with the use of round modules, as reported in a cost of ginning survey for 2016 (Valco, T.D., H. Ashley, D. Findley, J. Green, R. Isom, T. Price. The Cost of Ginning Cotton – 2016 Survey Results. 2018 Beltwide Cotton Conferences, San Antonio, TX, January 3-5, 2018. National Cotton Council, Memphis, TN. Pp. 528-53).

This suggests that making technology easier to use and offering factory-installed options can encourage more farmers to adopt it.

In the ginning cost survey, it was noted that round module utilization was reported as 51% in the Southeast, 61% in the Mid-South, 36% in the Southwest, and 29% in the Far West, aligning with the rankings of yield monitor adoption in Figure 2.

However, according to survey respondents, the adoption of yield monitor technologies increased across all four regions. This increase occurred because yield monitors only became available as a factory-installed option with the introduction of module-building harvesters.

Meanwhile, it is anticipated that the increased implementation of data-collecting technologies on agricultural equipment will lead to future increases in technology adoption.

The next stage of precision farming is expected to be influenced by advancements in automation technologies. Automation, which involves the use of machines to perform tasks automatically without human intervention, has the potential to greatly improve efficiency and precision in agricultural practices. One example is the integration of driverless tractor technology.

This technology can streamline tasks such as planting, spraying, and harvesting. As a result, these tasks can be performed with greater accuracy and efficiency. However, while automation offers numerous benefits, it’s important to consider its impact on employment in agriculture.

The 2023 survey introduced some new questions to cotton farmers about the advantages and challenges of using driverless tractors on their farms. More than 50% of respondents reported labor savings as one of the expected benefits of driverless tractors.

Furthermore, 41% cited improved efficiency, 28% highlighted decreased worker exposure, and 34% considered the technology to have no benefits. Meanwhile, it is likely that growers who have already invested in large swath equipment (e.g., sprayers with 120-foot booms) would see minimal benefits from eliminating an operator from such a machine.

Research is underway to determine if greater benefits can be achieved from automation by reducing equipment size, thus making it more scalable to the task and field size. Moreover, having several smaller pieces of equipment reduces the risk of downtime.

However, when a large piece of equipment fails, production on hundreds of acres a day is lost. The scale of equipment will likely be a balance between the number of units that need to be managed, the task to be completed, and the average field sizes and shapes on the farm.

Impediments to Driverless Tractors

In general, responses were consistent across regions, except for field obstacles and field-to-field transportation concerns. The increased concern in the Southeast and Mid-South is likely due to more water features and topography changes that affect fields in those regions compared to the Southwest and Far West. Across all regions, there is consensus that the costs of the technology could be an impediment to its use on their farms.

A question came up about which tasks should be automated first. People said planting (40%), spraying (40%), harvesting (35%), and pre-plant weed control (35%) are the main ones.

However, since we’re just starting to use automated farming equipment, it’ll be interesting to see how things change in the next five years. Meanwhile, the growing number of systems for spotting and spraying weeds using machine vision shows how fast these technologies are advancing.

Conclusion

Cotton Incorporated’s surveys from 2008 to 2023 reveal a growing adoption of precision agricultural technology among cotton farmers, particularly in tasks like planting, spraying, and harvesting. Autosteer technology has seen a significant increase in use, indicating a trend toward more efficient farming. However, challenges such as equipment scalability and costs remain.

The future of farming is likely to involve automation technologies like driverless tractors, offering benefits such as labor savings and improved efficiency but raising concerns about employment and equipment scalability.

Source: Cotton Grower and Cotton Incorporated. Researchers: Jeyran Bayramova, Steven Pires, Jesse Daystar, and Ed Barnes are researchers with Cotton Incorporated.

Precision Farming