For many years, tillage has been one of the most common field operations in agriculture. Farmers traditionally prepare their land by plowing, ripping, or cultivating the entire field at the same depth and intensity. This approach, known as uniform or whole-field tillage, is simple to manage and easy to plan. The basic assumption behind this method is that the soil condition is the same across the entire field.

Introduction: The Problem of Uniform Tillage

However, modern soil science and field data clearly show that this assumption is incorrect. Soil conditions are rarely uniform, even within small fields. Differences in soil texture, moisture, organic matter, slope, drainage, and machinery traffic create large variations in soil structure. One of the most important and damaging results of this variability is soil compaction.

Soil compaction does not occur evenly. Some areas become heavily compacted due to repeated machinery traffic, especially headlands and tramlines. Other areas may remain loose and well-structured. When a farmer applies the same tillage depth everywhere, some areas receive too much tillage, while others receive too little.

The cost of applying uniform tillage to this inherently variable problem is substantial, measured in both economic and ecological terms. In areas with naturally good structure or minimal compaction, deep tillage represents pure waste—it burns diesel fuel that could be saved, consumes labor hours that could be allocated elsewhere, accelerates the breakdown of valuable soil organic matter through excessive oxidation, destroys the intricate architecture of soil aggregates that took years to form, and leaves the soil surface bare and vulnerable to erosive forces of wind and water. Studies have shown that deep tillage can use 30–50% more fuel than shallow tillage, making unnecessary deep tillage a major economic burden.

Recent studies from the USDA’s Agricultural Research Service indicate that unnecessary tillage can accelerate soil organic matter loss by 2-4% annually in vulnerable soils. Conversely, in areas with severe subsurface compaction—the hard pans that form 8-16 inches below the surface—uniform shallow tillage fails completely. It skims the surface while leaving the root-restricting layer intact, creating what farmers call “false tilth” that looks good superficially but does nothing to address the underlying constraint on root growth and water movement.

This brings us to the precision agriculture solution that is reshaping modern tillage philosophy: Variable Rate Tillage (VRT). VRT represents a fundamental shift from blanket applications to targeted interventions. It applies the precise type, depth, and intensity of soil disturbance only where it is diagnostically justified by soil condition data. At the heart of this approach lies soil compaction mapping—the systematic measurement and spatial analysis of soil strength across fields.

What Is Soil Compaction?

Soil compaction occurs when soil particles are pressed closer together, reducing pore space. This makes the soil denser and harder for roots, air, and water to move through. Compacted soil has fewer large pores, which are essential for oxygen movement and water infiltration.

Compaction often happens below the surface, forming a hardpan layer that is invisible but highly restrictive to crops. Soil compaction is mainly caused by:

- Heavy machinery traffic, especially repeated passes

- Tillage and harvest operations on wet soil

- High axle loads from modern equipment

- Livestock trampling in some systems

- Low organic matter, which weakens soil structure

Fields with fine-textured soils (clay and silt) are more prone to compaction than sandy soils, especially when wet. Some of the common types of soil Compaction are:

- Surface Compaction: Occurs in the top 5–10 cm of soil. It affects seed emergence and early root growth.

- Subsoil Compaction: Occurs deeper (20–40 cm) and is more serious. It restricts deep root growth and water movement and can persist for many years if not corrected.

The Foundation: Mapping Soil Compaction

The foundational principle of precision agriculture is that you cannot effectively manage variability you have not measured. Before any intelligent tillage decisions can be made, a farmer must develop a detailed, accurate understanding of how soil compaction varies across their land. This requires moving beyond occasional probe checks and subjective assessments to systematic, data-rich mapping of soil strength at relevant depths throughout the entire production area.

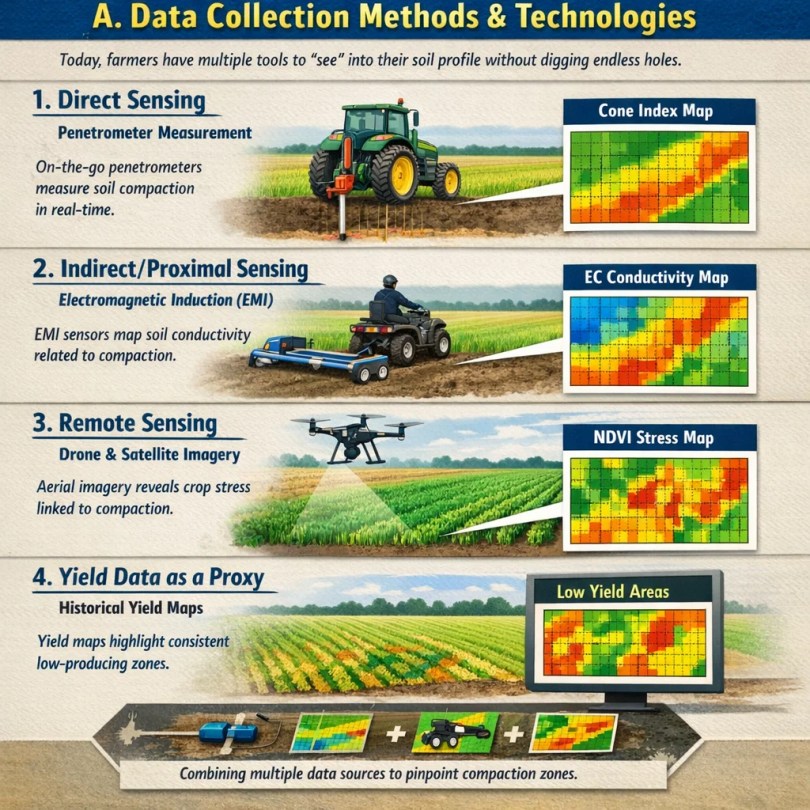

A. Data Collection Methods & Technologies

Today, farmers have multiple tools to “see” into their soil profile without digging endless holes.

1. Direct Sensing: On-the-go penetrometers are the gold standard for measuring compaction. Mounted on a tractor, UTV, or dedicated sled, these instruments push a standardized cone into the soil and measure the resistance (called cone index) at various depths. Modern systems, like those from Veris Technologies or Topcon, record thousands of data points per acre along with GPS coordinates, creating a dense, high-resolution map of soil strength.

Recent 2024 data from the Precision Agriculture Association indicates that penetrometer-based mapping, when done at proper soil moisture (near field capacity), achieves over 92% accuracy in identifying compacted zones that limit root growth.

2. Indirect/Proximal Sensing: Electromagnetic Induction (EMI) sensors, which map soil electrical conductivity (EC), are powerful proxy tools. While EC is influenced by clay content, moisture, and salinity, it often correlates strongly with compaction zones. Wet, compacted clay areas typically show high EC. Companies like Geonics, Dualem, and Veris offer implements that generate EC maps quickly, providing a foundational layer of soil variability data.

According to 2023 research from the University of Nebraska-Lincoln, when EMI data is calibrated with strategic penetrometer measurements and combined with soil texture maps, it can predict compaction zones with 85-90% reliability, making it an excellent reconnaissance tool.

3. Remote Sensing: Satellite and drone imagery can reveal the symptoms of compaction. Areas of stunted crop growth, premature senescence, or elevated canopy temperature (indicating plant stress) often trace back to restricted roots in compacted soil. Analyzing time-series imagery, especially early in the season, can help identify chronic problem zones.

Modern analytical platforms like Solvi, Sentera, or John Deere’s See & Spray Premium can process time-series imagery to identify persistent problem zones that correlate strongly with soil compaction. A 2024 study published in the “Journal of Precision Agriculture” demonstrated that combining three years of drone-collected NDVI data correctly identified 87% of moderate-to-severe compaction zones verified by ground truthing.

4. Yield Data as a Proxy: Historical yield maps are a valuable, readily available source of clues. Persistent low-yielding spots, particularly in years with adequate rainfall, are frequently caused by undiagnosed subsoil compaction. These “chronic underperformers” on yield maps serve as excellent starting points for targeted compaction investigation. When layered with other data, yield history helps distinguish compaction effects from nutrient deficiencies or disease issues.

B. Creating the Soil Compaction Prescription Map

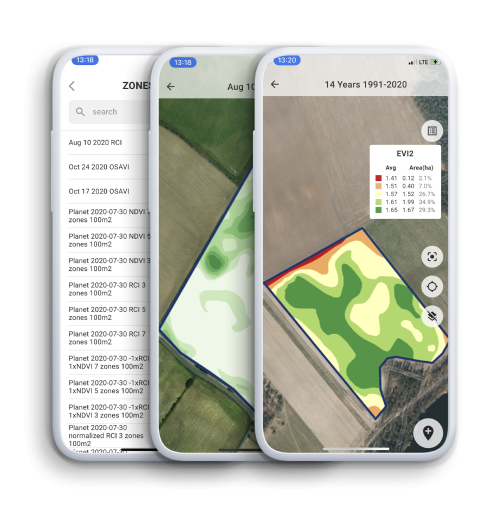

The transition from raw data to an actionable tillage prescription requires sophisticated data fusion and agronomic interpretation. This process typically occurs in agricultural GIS software platforms like Geopard, ArcGIS Agribot, or cloud-based systems such as Climate FieldView or Granular. The most robust prescription maps emerge from integrating multiple complementary data layers:

- A primary layer from an EMI or penetrometer survey.

- Historical yield map data for context.

- A soil type map to differentiate texture-based EC changes from compaction-based changes.

- Topography data, as lower landscape positions are more prone to compaction.

Using this integrated data, the field is divided into distinct management zones. A simple three-zone system might be:

- Zone 1: No-Till Preservation Areas (30-50% of many fields): Characterized by low penetration resistance (<300 psi at all depths), good drainage, and stable structure. These areas receive zero tillage to protect soil health and organic matter.

- Zone 2: Shallow Tillage Zones (30-40% of fields): Exhibiting moderate surface compaction (300-600 psi in top 6 inches) but reasonable subsoil conditions. Targeted for vertical tillage, discing, or shallow cultivation (3-6 inches) to alleviate surface crusting while preserving subsoil structure.

- Zone 3: Deep Intervention Zones (10-30% of fields): Showing severe subsoil compaction (>600 psi at 8-16 inch depth), often with visible plow pans or traffic layers. Designated for deep ripping, subsoiling, or paraplowing (8-18 inches) to fracture compacted layers and restore vertical porosity.

A critical consideration is soil moisture. All compaction readings must be taken when the soil is near field capacity (moist but not saturated) to ensure accuracy. Data should always be validated with manual penetrometer checks in each suspected zone. For accurate, comparable data, sensing should occur when the soil is near field capacity (the moisture condition after free drainage has occurred but before significant drying). Many leading consultants now recommend “dual-season” sensing—mapping in both spring (typically wetter) and fall (typically drier) to develop a more complete understanding of how compaction manifests under different conditions.

The Execution: Variable Rate Tillage Technology

With a validated prescription map in hand, the next phase involves the physical implementation—translating digital prescriptions into precise mechanical action across the landscape. This requires specialized equipment systems that combine robust tillage implements with sophisticated control technology.

A. Hardware: The “How” of Variable Tillage

Variable Depth Tillage: This is the most common application. Leading manufacturers like John Deere (with their ExactEmerge platform adapted for tillage), Case IH (Early Riser system), Unverferth (Zone Commander), and DuroTech (Intellivator system) offer implements where each shank is mounted on a hydraulic cylinder controlled by the tractor’s hydraulic system. As the tractor moves across the field, the in-cab controller automatically raises or lowers each shank to the depth specified in the prescription map for that exact location.

- 6 inches where compaction is low,

- 10–12 inches where there’s moderate compaction,

- 14+ inches where subsoil hardpan restricts root growth.

In practice, this might mean shanks running at 6 inches in non-compacted zones, automatically extending to 10 inches as they enter a moderately compacted area, then reaching 16 inches in severe hardpan zones—all seamlessly within a single pass. Advanced systems feature “profile-based” control that not only sets maximum depth but controls the depth curve to match specific hardpan characteristics.

Variable Intensity Tillage: Some systems go beyond just depth. They can change the aggressiveness of the tillage action. This might involve automatically engaging or disengaging individual rows of shanks, or switching between different types of tools (e.g., from a deep-cutting coulter to a full-width sweeper) based on the zone.

The most advanced systems, like Väderstad’s adaptive system or the progressive tillage concept from several European manufacturers, can automatically adjust the angle of attack, vibration frequency, or even switch between completely different tool types (e.g., from an inversion plow to a non-inversion subsurface loosener) based on the prescription. While less common in North America, these systems represent the cutting edge of tillage precision.

B. Software & Control: The “Brain” of the Operation

The system is orchestrated from the tractor cab. The prescription map is loaded onto the farm management software (like John Deere Operations Center, CNH AFS, or Trimble Ag Software) on the in-cab display. Using a high-accuracy RTK-GPS signal for precise positioning, the controller knows the tractor’s location within inches. The implement and tractor communicate via the ISO 11783 (ISOBUS) protocol, a universal “plug-and-play” language for agricultural electronics. The workflow is straightforward and this integrated system ensures accuracy and reduces operator fatigue and guesswork:

1. Pre-Operation Planning: The agronomist or farmer finalizes the prescription map, ensuring zones are logically defined with appropriate buffers between depth changes to prevent excessive implement cycling.

2. Equipment Setup and Calibration: The implement is calibrated—depth sensors are verified, hydraulic response times are tested, and the system is put through test cycles to ensure shanks respond correctly to depth commands.

3. Field Execution: The operator simply selects the prescription map, confirms implement connection, and begins field work. The system handles all depth adjustments automatically. The operator monitors system performance, watching for proper shank response and making minor speed adjustments to optimize soil fracturing in different conditions.

4. Documentation and As-Applied Mapping: As the operation proceeds, the system creates a detailed “as-applied” map showing exactly what depth was applied at every point in the field. This documentation is crucial for evaluating effectiveness and planning future management.

How GeoPard Agriculture Enables Variable Rate Tillage for Soil Compaction

Soil compaction is one of the major constraints to crop productivity, affecting root development, water infiltration, and nutrient uptake. GeoPard Agriculture solves this challenge by enabling data-driven Variable Rate (VR) Tillage based on measured soil compaction at multiple depths. GeoPard’s VR Tillage workflow begins with a Soil Compaction dataset (or equivalent data) collected across the field at multiple depths.

This detailed subsurface information allows growers and agronomists to understand exactly where and how deeply soil compaction exists, rather than relying on assumptions or uniform tillage strategies. Using GeoPard, this data is seamlessly transformed into precise VR Tillage applications, ensuring that tillage depth is adjusted only where necessary.

1. Single-Field VR Tillage Applications

For individual fields, GeoPard provides an interactive, multilingual workflow that guides users step-by-step through the creation of a VR Tillage map. By analyzing soil compaction values at specific depths, GeoPard automatically generates prescriptions that optimize tillage depth across the field—reducing fuel use, equipment wear, and soil disturbance.

2. Batch VR Tillage Maps for Multiple Fields

GeoPard also supports batch processing, making it easy to create VR Tillage maps for multiple fields at once. With just a few clicks, users can generate consistent, scalable VR tillage prescriptions across an entire operation—ideal for large farms, service providers, and agronomy teams managing multiple locations.

3. Smart Tillage Depth Calculation with Custom Equations

A key strength of GeoPard is its custom equation library, which allows users to define how tillage depth responds to soil compaction values. For example, tillage depth can be calculated based on the 25 cm compaction measurement using a simple, transparent rule:

if pressure < 15:

tillage_depth = 25

elif pressure < 21:

tillage_depth = 27

else:

tillage_depth = 30

This equation—or any variation of it—can be saved and reused in GeoPard, ensuring consistent decision-making while remaining fully customizable to local soil conditions, equipment, and agronomic strategies. By integrating soil compaction data with Variable Rate Tillage technology, GeoPard Agriculture helps growers:

- Reduce unnecessary deep tillage

- Improve soil structure and root development

- Lower fuel and operational costs

- Protect soil health and long-term productivity

The Benefits: Why Implement This System?

The adoption of compaction-based VRT delivers measurable advantages across multiple dimensions of farm performance. These benefits compound over time, creating what economists call “increasing returns to adoption.”

Agronomic & Environmental Benefits:

1. Enhanced Soil Health: Minimizing disturbance in non-compacted zones protects soil organic matter, microbial communities, and earthworm habitats. This builds long-term resilience. A 2024 study in “Soil Biology and Biochemistry” comparing VRT to uniform tillage found that mycorrhizal fungal colonization of corn roots was 40-60% higher in no-till VRT zones compared to tilled areas, with corresponding improvements in phosphorus uptake efficiency.

2. Reduced Erosion: By leaving approximately 30-50% of field areas undisturbed with surface residue intact, VRT significantly reduces erosion risk. Purdue University field trials (2022-2024) showed that VRT-managed fields absorbed rainfall 2-3 times faster than uniformly tilled fields during 1-inch per hour simulated rainfall events. This reduces surface runoff, decreases erosion, and increases plant-available water by an average of 0.8-1.2 inches per growing season—equivalent to a free irrigation event in many regions.

Furthermore, USDA Natural Resources Conservation Service models estimate that properly implemented VRT can reduce soil loss by 35-55% compared to full-field deep tillage, with corresponding reductions in phosphorus runoff of 40-60%.

3. Optimized Root Zones: Correcting compaction only where it exists allows for uniform root exploration and water infiltration, leading to more even crop emergence and development. University of Illinois research (2023) demonstrated that corn roots in VRT-managed zones reached depths 8-12 inches greater than in uniformly tilled fields, with corresponding improvements in drought resilience.

Economic Benefits:

1. Direct Input Savings: The most immediate economic benefit comes from reduced input consumption. By deeply tilling only the portion of the field that actually needs it, farmers save substantially on:

- Fuel Consumption: Multiple studies across the Midwest (Iowa State University, 2023; Ohio State University, 2024) document fuel savings of 25-45% on primary tillage operations, translating to $4-8 per acre in direct savings.

- Labor Requirements: Reduced tillage intensity and area covered decreases labor time by 20-35%.

- Equipment Maintenance: Reduced hours of operation and less strain on equipment components decreases repair and maintenance costs by an estimated 15-25% annually.

2. Yield Optimization: While eliminating unnecessary tillage preserves yield potential in good areas, addressing compaction in problem areas typically increases yields. Research compiled by the Precision Agriculture Association (2024) shows consistent yield improvements of 8-15% in previously compacted zones following targeted deep tillage. For a typical Midwestern corn field with 20% compaction problem area, this translates to an overall field yield increase of 1.6-3.0%. At $5.00/bushel corn, this represents $12-22 per acre in additional revenue.

A 2024 study from Purdue University Extension demonstrated that targeted subsoiling in compacted zones increased corn yields by an average of 12-18 bushels per acre in those zones, while eliminating unnecessary tillage in good areas preserved their yield potential.

3. Return on Investment (ROI): While the upfront cost for sensors and a compatible VRT implement can range from $20,000 to $80,000, the payback period can be swift. For a 1,000-acre corn and soybean farm, annual fuel and labor savings of $5,000-$8,000, combined with a conservative yield increase of 2-3% from better compaction management, can create an ROI within 3-5 years. The investment also future-proofs equipment for the data-driven era of farming.

Challenges and Practical Considerations

Adopting this technology is not without its hurdles.

Upfront Investment: The cost of sensors, compatible implements, and high-accuracy RTK-GPS guidance is significant and can be a barrier for smaller operations. Farmer cooperatives in regions like the Red River Valley have successfully pooled resources to purchase VRT equipment for member use.

Data Complexity: Turning raw sensor data into an accurate, actionable prescription map requires agronomic expertise. Farmers may need to partner with agronomists or consultants. The learning curve is real but manageable. Most successful adopters emphasize starting with a single demonstration field in year one, expanding to 20-30% of acreage in year two, and full implementation by year three or four.

Critical Timing Considerations: Soil moisture at tillage execution is arguably more critical for VRT than uniform tillage. If soil is too wet, deep tillage in compacted zones will create smearing rather than fracturing. If too dry, excessive energy is required and soil may pulverize. The optimal moisture window—typically when soil is at or slightly below field capacity—may be narrow. Advanced operations use soil moisture sensors and forecasting to identify optimal tillage windows, sometimes operating at night or during unconventional hours to hit the moisture sweet spot.

The Limitations of Corrective Tillage: Perhaps the most important conceptual understanding is that VRT for compaction addresses symptoms. The most sophisticated systems still represent corrective rather than preventive management. Truly sustainable soil management requires integrating VRT with:

- Controlled Traffic Farming (CTF): Permanently confining wheel traffic to specific lanes, dramatically reducing future compaction.

- Cover Cropping: Building soil structure and organic matter to resist compaction.

- Improved Harvest Logistics: Reducing axle loads and avoiding field operations in wet conditions.

- Organic Matter Management: Building the “biological glue” that helps soil resist compaction.

Farmers who use VRT as part of a comprehensive soil health system typically find they can reduce the frequency of deep intervention over time as overall soil resilience improves.

Future of Emerging Technological Trends

The future of compaction-based tillage is intelligent and integrated. Emerging trends include the coupling of real-time, on-the-go compaction sensors with implements that adjust depth instantly—creating a true “sense-and-act” system in one pass.

Real-Time, Integrated Sensing and Response: The holy grail of VRT is closing the loop between sensing and action in real time. Prototype systems now in field testing combine ground-penetrating radar or continuous penetrometry with instantly adjustable implements. These “sense-and-act” systems create compaction maps on the first pass and execute tillage on the second pass, or in some advanced prototypes, perform both simultaneously. Companies like AgDNA and some European manufacturers have demonstrated working systems that could commercialize within 3-5 years.

Artificial Intelligence and Machine Learning Optimization: AI is transforming prescription development. Rather than relying solely on human interpretation of data layers, machine learning algorithms can now identify complex, nonlinear relationships between soil properties, historical management, and compaction outcomes. Systems like IBM’s Watson for Agriculture and several startup platforms can analyze decades of field data to predict where compaction is likely to (re)develop, enabling preventive rather than reactive management.

Autonomous Tillage Platforms: The convergence of autonomy and VRT promises to revolutionize tillage economics and timing. Small, lightweight autonomous tillage robots could work in optimal soil moisture conditions 24/7 without operator fatigue. European trials with companies like Agrointelli and FarmDroid have shown promising results with solar-powered autonomous implements performing targeted tillage at precisely the right soil moisture.

Integration with Carbon Farming and Ecosystem Services Markets: As carbon credit markets mature, precisely documented reductions in tillage intensity through VRT create verifiable carbon sequestration claims. Early-adoption data suggests VRT can reduce soil carbon loss by 0.2-0.4 metric tons per acre annually compared to full-field tillage. When carbon markets reach $50-100 per metric ton (as projected by several analysts for 2030), this could add $10-40 per acre in ecosystem service payments to the VRT value proposition.

Conclusion

In conclusion, variable rate tillage guided by soil compaction data represents a fundamental paradigm shift. It moves soil management from a reactive, uniform practice to a proactive, prescription-based strategy. It acknowledges the inherent variability of the land and treats each square foot according to its specific need. By adopting this approach, farmers position themselves at the forefront of site-specific conservation agriculture, making strategic decisions that enhance both the profitability of their business and the long-term sustainability of their most valuable asset: the soil. It is a powerful step toward farming that is not only more precise but also more intelligent.

VRA